Basfiber® - Chopped Fiber

Our concrete-grade basalt chopped fiber is specially designed for production of fiber reinforced concrete to provide outstanding performance in a wide range of applications. This basalt chopped fiber is produced with a special sizing agent to provide good compatibility with different types of concretes and easy mixing even at high

content.

Kamenny Vek provides various types of yarns and woven fabrics for fire protection, thermal and sound insulation. Basfiber® has higher sound insulation properties, 150°C more heat resistance than glass fibers.

Advanced basalt UD-tapes are ideally suited for renovation of old concrete structures and for reinforcing of concrete walls.

Basfiber® significantly outperforms synthetic materials by their ability to withstand low temperatures that is extremely

important for roads and highways in the north regions.

content.

Kamenny Vek provides various types of yarns and woven fabrics for fire protection, thermal and sound insulation. Basfiber® has higher sound insulation properties, 150°C more heat resistance than glass fibers.

Advanced basalt UD-tapes are ideally suited for renovation of old concrete structures and for reinforcing of concrete walls.

Basfiber® significantly outperforms synthetic materials by their ability to withstand low temperatures that is extremely

important for roads and highways in the north regions.

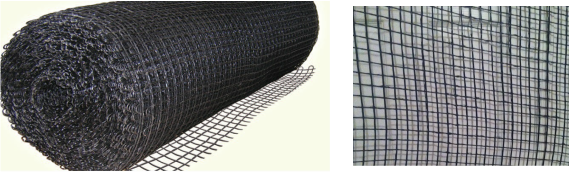

BasGrid™ - 100mm,25mm,04mm square grids or custom shapes

GeoGrids

Basalt BasGrid™ is designed for reinforcing road and highway overlays to prolong the pavement life span by reducing the effects of cracking caused by traffic loading, age, hardening and temperature cycling. Pavement life between maintenance can be prolonged significantly.

Basalt reinforcing mesh makes it possible to reduce thickness of asphalt or concrete pavement up to 20%. Typical paving temperatures will not cause any loss of strength or distortion which may occur with other synthetic material.

Follow the Link for more information about BasGrid™ and Geo Grids. http://www.basfiber.com/src/geotextile.pdf

Basalt reinforcing mesh makes it possible to reduce thickness of asphalt or concrete pavement up to 20%. Typical paving temperatures will not cause any loss of strength or distortion which may occur with other synthetic material.

Follow the Link for more information about BasGrid™ and Geo Grids. http://www.basfiber.com/src/geotextile.pdf

ReforceTech Products - MiniBars™

MiniBars™ - Basalt FRP Macrofiber by ReforceTech

Unique new macrofiber made from 0.65mm thin Basalt FRP wires are available in long (43mm) lengths for concrete and short (20mm) for grout and mortar mixes. In contrast to microfiber that is used primarily for shrinkage crack control during curing at early ages, these macrofibers will significantly enhance both Flexural Tensile (FTS) and Average Residual Strength (ARS), often allowing the complete elimination of WWR mesh and light structural rebar. We call it “Pre-Reinforced™” concrete!

Compared to steel fiber, MiniBars™ can be mixed at much higher dosages and still be pumped without clogging equipment. Finishing without exposing the fibers is also easy as they stay suspended in the matrix below the surface.

In addition to concrete slabs on grade or structure, MiniBar™ mixes have been used very successfully in a variety of wall applications including cast-in-place and precast architectural facades, insulated wall panels, structural (shear) walls and privacy barriers. Any concrete in an exposed or marine environment is a prime use for MiniBar™ reinforced concrete.

Accelerated aging tests show high resistance to both alkaline and acid environments. Unlike steel fibers, MiniBars™ will never rust and cause aesthetic or structural problems.

Projects using MiniBars™ have shown up to 20% savings in overall cost when considering both materials and labor. The cross section of the members can often be reduced because concrete cover normally required for steel is not necessary. There is no labor to fabricate and place reinforcing, just pour or pump the MiniBar™ Pre-Reinforced™ concrete in the forms and finish.

BasBar™ Basalt FRP Reinforcing Bars by ReforceTech

This non-metallic rebar is twice as strong as steel, but only 25% of the weight, so smaller bars can be used and shipping costs are greatly reduced. ReforceTech uses a new manufacturing process that is certified by Det Norske Veritas (DNV) and ISO 9008. Bars are available in standard US and custom metric sizes and shapes.

We also have available for engineers the first Basalt FRP Design Guide based on ACI 440.1R-06 that includes all the specific coefficients for Basalt in addition to other types of fiber. Please e-mail us to receive your copy

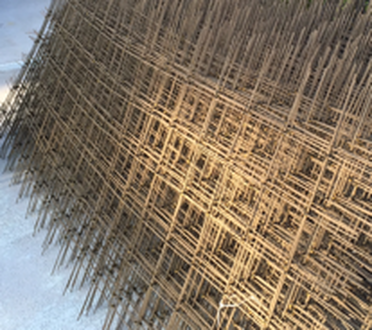

In addition to straight and bent bars, we also offer custom pre-tied (taped) cages or mesh.

GALEN Composites

ROCKBAR® / MESH GRIDS / Composite Wall Ties

Composite rebar (BFRP) produced using a pultrusion method from 2.5mm through 25mm in various shapes and sizes to meet your specifications.

Please keep in mind, all bent shapes must be ordered and bent at the factory at the time the bar is produced.

BFRP or GFRP can't be field bent.

In addition to straight and bent bars, we also offer custom cages or mesh.

Unique new macrofiber made from 0.65mm thin Basalt FRP wires are available in long (43mm) lengths for concrete and short (20mm) for grout and mortar mixes. In contrast to microfiber that is used primarily for shrinkage crack control during curing at early ages, these macrofibers will significantly enhance both Flexural Tensile (FTS) and Average Residual Strength (ARS), often allowing the complete elimination of WWR mesh and light structural rebar. We call it “Pre-Reinforced™” concrete!

Compared to steel fiber, MiniBars™ can be mixed at much higher dosages and still be pumped without clogging equipment. Finishing without exposing the fibers is also easy as they stay suspended in the matrix below the surface.

In addition to concrete slabs on grade or structure, MiniBar™ mixes have been used very successfully in a variety of wall applications including cast-in-place and precast architectural facades, insulated wall panels, structural (shear) walls and privacy barriers. Any concrete in an exposed or marine environment is a prime use for MiniBar™ reinforced concrete.

Accelerated aging tests show high resistance to both alkaline and acid environments. Unlike steel fibers, MiniBars™ will never rust and cause aesthetic or structural problems.

Projects using MiniBars™ have shown up to 20% savings in overall cost when considering both materials and labor. The cross section of the members can often be reduced because concrete cover normally required for steel is not necessary. There is no labor to fabricate and place reinforcing, just pour or pump the MiniBar™ Pre-Reinforced™ concrete in the forms and finish.

BasBar™ Basalt FRP Reinforcing Bars by ReforceTech

This non-metallic rebar is twice as strong as steel, but only 25% of the weight, so smaller bars can be used and shipping costs are greatly reduced. ReforceTech uses a new manufacturing process that is certified by Det Norske Veritas (DNV) and ISO 9008. Bars are available in standard US and custom metric sizes and shapes.

We also have available for engineers the first Basalt FRP Design Guide based on ACI 440.1R-06 that includes all the specific coefficients for Basalt in addition to other types of fiber. Please e-mail us to receive your copy

In addition to straight and bent bars, we also offer custom pre-tied (taped) cages or mesh.

GALEN Composites

ROCKBAR® / MESH GRIDS / Composite Wall Ties

Composite rebar (BFRP) produced using a pultrusion method from 2.5mm through 25mm in various shapes and sizes to meet your specifications.

Please keep in mind, all bent shapes must be ordered and bent at the factory at the time the bar is produced.

- Absolute corrosion resistance, alkali resistance;

- Forecasted durability exceeds 75 years;

- Less maintenance, reduction of costs for current maintenance and repair;

- Reduction of transportation costs;

- Easy to install.

BFRP or GFRP can't be field bent.

In addition to straight and bent bars, we also offer custom cages or mesh.

In Partnership with Brevard Achievement Center the manufacturing of custom Basalt Grids we can custom make all your Basalt Grids for your applications!

We at BPG LLC are exciting about this opportunity to work with our community and provide meaningful work for many people and to provide many products that can be used around the country.

Grids can be produced in the USA by our partnership with the Brevard Achievement Center, with them as our partner we are using Adults with disabilities and making them productive. They look forward to meet your needs with specialty grids.

Basfiber® Rovings

Basfiber® Rovings are available in many different tex (fiber counts) to meet your specific requirements. Further basalt roving can be processed to roving fabrics or reinforcing net. Rovings can also be used in conjunction with portable chopping guns for layup or sprayed application like those used in GFRC panels or tunnel linings.

Basfiber Rovings are available in configurations of both a internal and external wind to meet your needs.

Basfiber Rovings are available in configurations of both a internal and external wind to meet your needs.